The silent backbone of modern industries

In almost every product we use daily—whether it’s a smartphone case, a car dashboard, or even the medical syringe at a hospital—plastic molded parts are silently at work. These components, often overlooked by end-users, are critical to the functionality, durability, and affordability of countless applications. Behind the scenes, a plastic molded parts manufacturer ensures that industries get high-quality, precision-engineered parts tailored to their needs.

From automotive and consumer electronics to aerospace and healthcare, industries rely heavily on these manufacturers because they provide more than just parts. They provide efficiency, innovation, and cost advantages that would be difficult to achieve otherwise. Understanding why industries trust a plastic parts company can shed light on the central role these specialists play in the global supply chain.

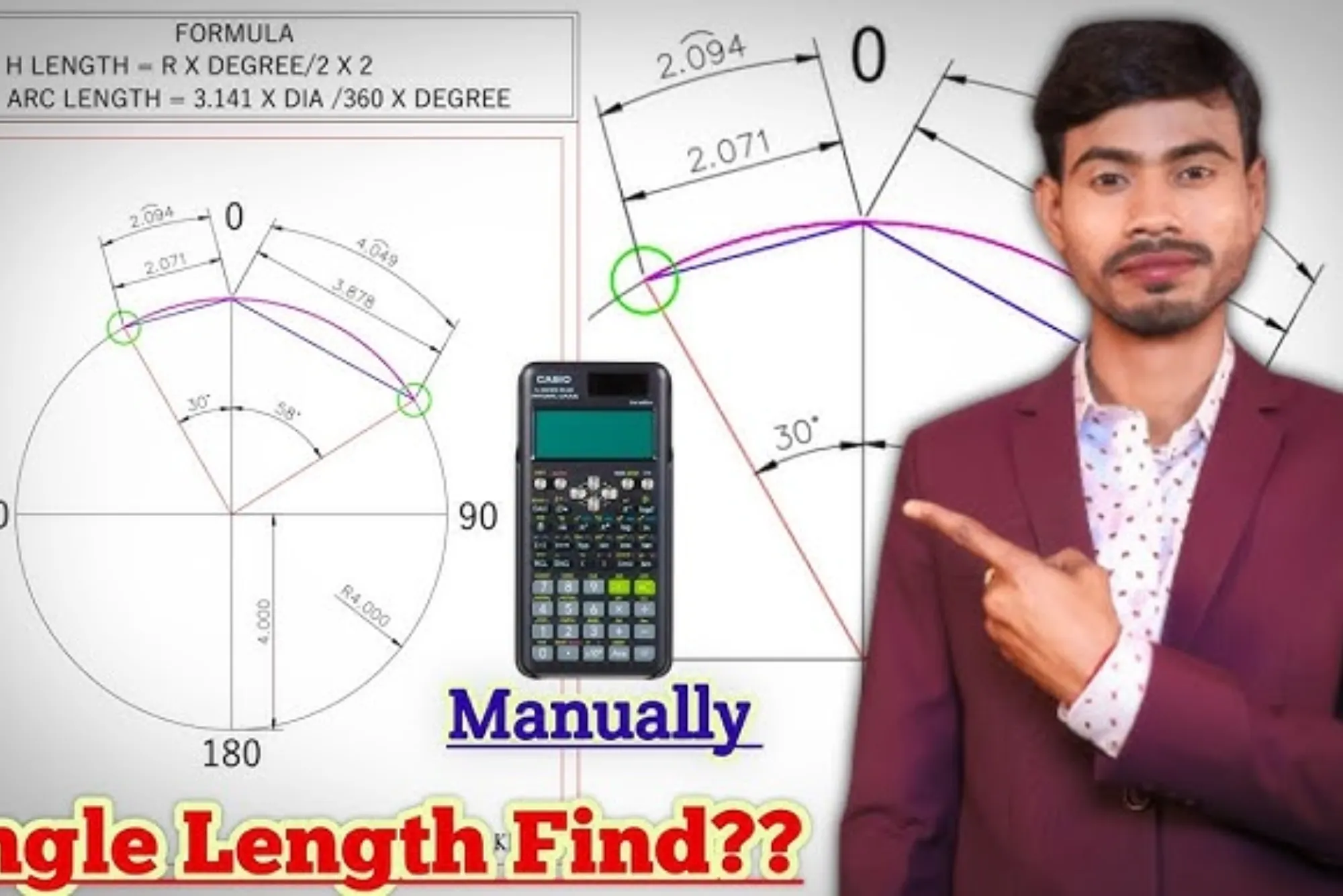

Consistency and precision at scale

One of the biggest reasons industries turn to a plastic molded parts manufacturer is consistency. Mass production requires parts that are not only identical but also precise down to millimeter tolerances. Whether it’s the casing for an electronic device or the intricate clips in an automobile’s interior, even a minor defect can disrupt assembly lines or cause costly recalls.

Plastic molding, particularly injection molding, makes it possible to produce thousands or even millions of identical parts with repeatable accuracy. This level of precision is why a plastic parts company is considered an extension of the manufacturing process itself, ensuring supply chains remain reliable and products meet stringent quality standards.

Cost-effectiveness without compromising quality

Plastic, compared to metal or composite materials, offers a unique balance of durability and affordability. The initial tooling cost for molds can be significant, but once the mold is perfected, the cost per unit drops dramatically with higher volumes. This economic advantage is why industries—from packaging to electronics—partner with a plastic molded parts manufacturer to reduce production costs while maintaining quality.

Moreover, advanced material engineering allows these manufacturers to select plastics with properties such as heat resistance, chemical stability, or impact strength. This adaptability ensures that cost savings don’t come at the expense of performance. A seasoned plastic parts company knows how to strike this balance, helping businesses remain competitive in crowded markets.

Innovation and customization capabilities

Today’s products demand more than standard parts; they require customized solutions. A plastic molded parts manufacturer brings innovation into the mix by designing molds that accommodate complex geometries, textured surfaces, or lightweight yet strong structures.

Consider the automotive industry, where reducing weight is essential for fuel efficiency. Plastics replace metals in non-load-bearing components without sacrificing performance. Similarly, in consumer electronics, sleek designs with precise tolerances would be impossible without plastic molding expertise.

A trusted plastic parts company doesn’t just produce components; it collaborates with clients in product development, offering input on material selection, prototyping, and design optimization. This partnership is what makes industries stick with experienced manufacturers over short-term alternatives.

Meeting strict regulatory and safety standards

Industries such as medical devices, aerospace, and food packaging face strict regulatory requirements. Here, the role of a plastic molded parts manufacturer becomes indispensable. These manufacturers must not only deliver consistent quality but also comply with international standards like ISO certifications, FDA approvals, or RoHS compliance.

A syringe or a ventilator component, for instance, must be manufactured under sterile conditions with biocompatible materials. A plastic parts company with expertise in regulatory compliance ensures that industries can introduce their products to the market without facing legal or safety setbacks. Trust is built not just on technical skill but also on accountability and adherence to standards.

Efficiency and speed in production cycles

Speed is often a decisive factor in industrial supply chains. Delays in component production can halt entire assembly lines, costing millions. By relying on a plastic molded parts manufacturer, industries can access streamlined processes such as automated injection molding, real-time quality checks, and just-in-time delivery systems.

For example, in consumer goods, product cycles are shorter than ever. A new design may need to go from prototype to market in a matter of weeks. Partnering with a responsive plastic parts company ensures that businesses can meet these timelines without compromising quality. This agility is a significant reason industries stay loyal to their manufacturing partners.

Sustainability and eco-conscious solutions

In recent years, sustainability has become a priority across sectors. Many industries now expect their suppliers to adopt eco-friendly practices. A forward-thinking plastic molded parts manufacturer invests in recyclable materials, energy-efficient production lines, and waste reduction processes.

A plastic parts company that demonstrates a commitment to sustainability not only helps industries reduce their carbon footprint but also aligns with consumer expectations for environmentally responsible products. This shift shows that reliance on manufacturers is not just about function and cost—it’s also about values and long-term environmental impact.

Real-world examples of reliance

To put this into perspective, consider three industries:

-

Automotive: From dashboards and air vents to fuel system components, cars today use hundreds of plastic molded parts. Without specialized manufacturers, automakers couldn’t achieve the precision, safety, or cost-efficiency they need.

-

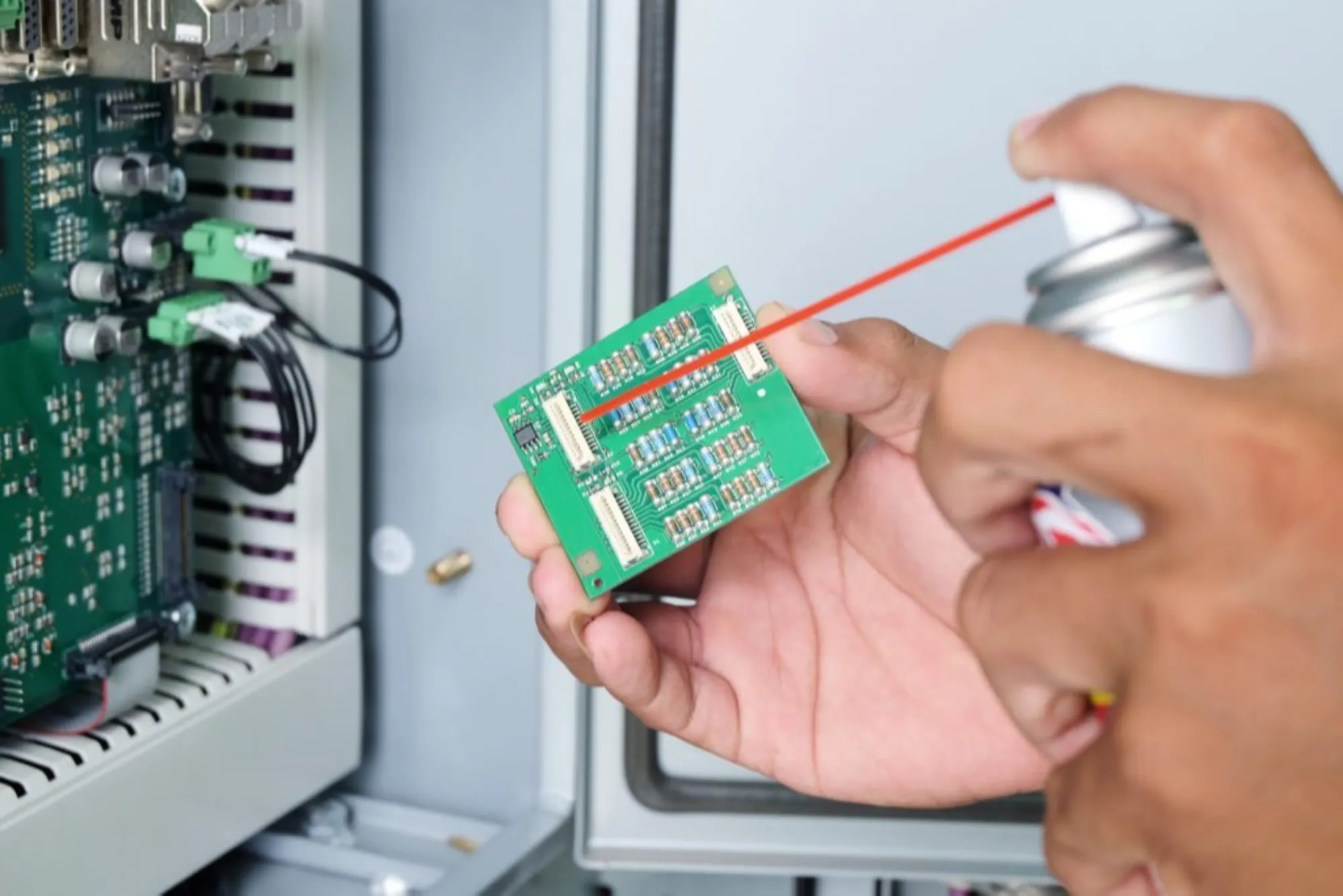

Healthcare: Syringes, IV connectors, and diagnostic device housings must meet strict sterility and safety standards. A specialized plastic parts company ensures these life-saving tools are reliable.

-

Consumer electronics: Sleek phone cases, precise buttons, and durable connectors all rely on plastic molding expertise. Without it, design and usability would suffer.

Each of these industries demonstrates that plastic molded parts aren’t just accessories—they are core to how modern products function and perform.

Final thoughts: the unseen yet vital partnership

Industries rely on plastic molded parts manufacturers not just because they need parts, but because they need trust, innovation, compliance, and efficiency. The relationship between a business and a plastic parts company goes far beyond a transactional supplier arrangement. It’s a strategic partnership that ensures products reach the market faster, meet safety standards, and remain cost-competitive.

In short, plastic molded parts manufacturers are the silent enablers of industrial success, shaping the everyday objects we often take for granted. Their role may not always be visible, but without them, modern industry simply wouldn’t function.